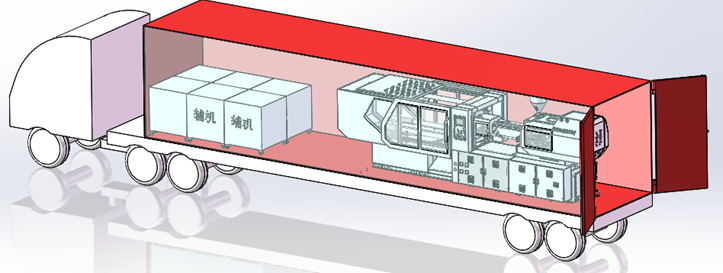

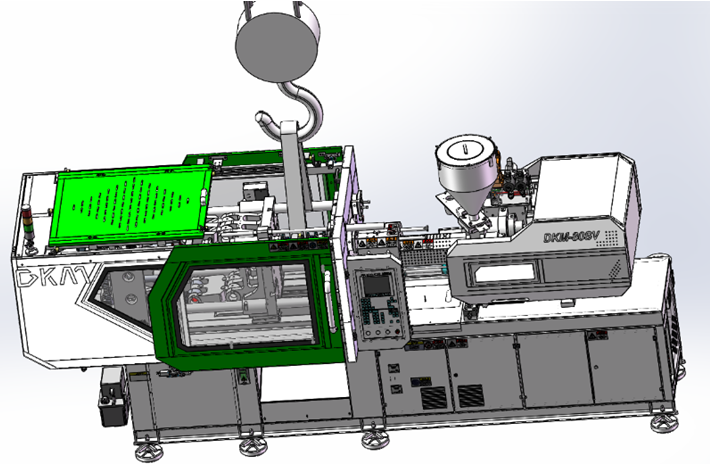

DKM-180SV Unloading and Installation Process

DKM-180SV Preparation for Unloading Process

1. Equipment with 5-10T forklift

2. Equipped with 10T crane or 10-20T driving

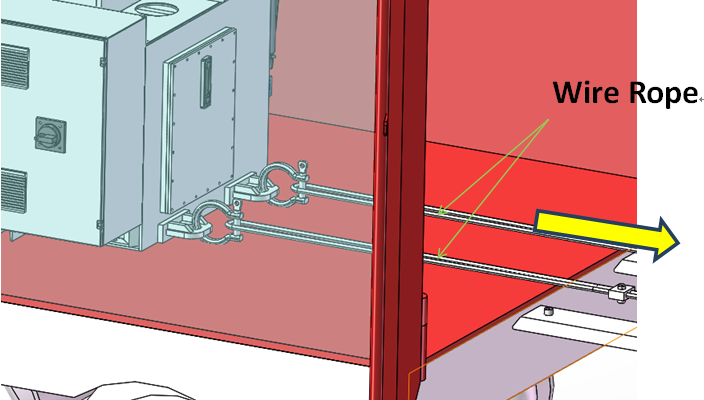

3. Need to prepare 5-10T harness 2pieces, length is about 5-10m, then to prepare φ16 wire rope 2pieces, length is about 10-20m, and also prepare 2 pieces Jack of 5-10T.

4. Unloading in factory by using crane, this required plant door 8m height or more, door width 6m or more, plant floor height 15m height or more.

Unloading in factory by using driving, this required plant door 8m height or more, door width 6m or more, plant floor height 10m height or more.

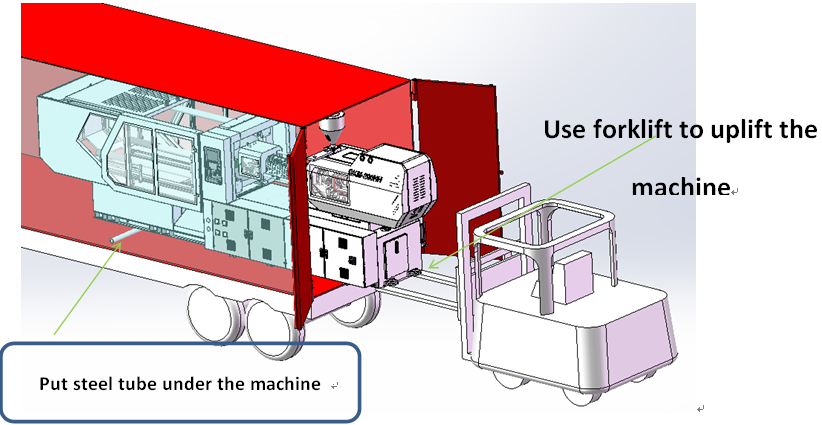

Remove wooden piece

Fix the wire on the hook at the bottom of the clamping frame

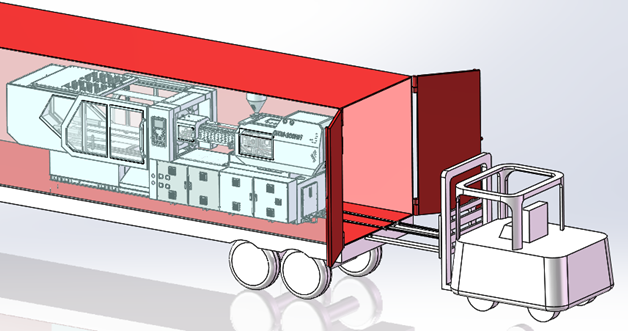

The other end of the wire rope is fixed on the forklift and the forklift pulls the machine out

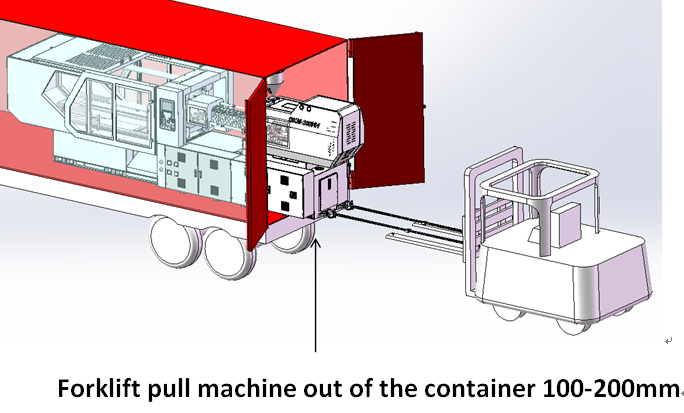

When the forklift pull machine out of the container 100-200mm, it needs remove the rope, forking machine from the top, and put steel pipe under the machine.

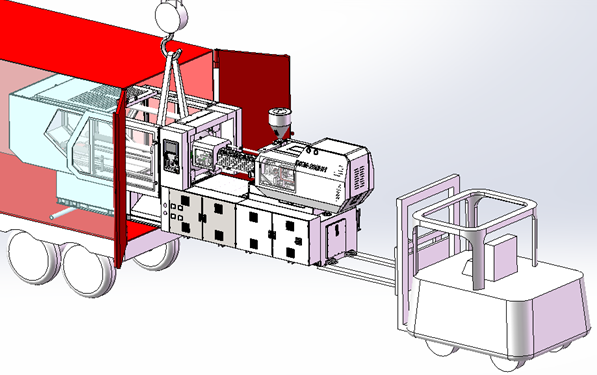

Carefully and slowly move out the machine by forklift, when the tie bars are out of container, then use crane to sling the machine and move together with forklift.

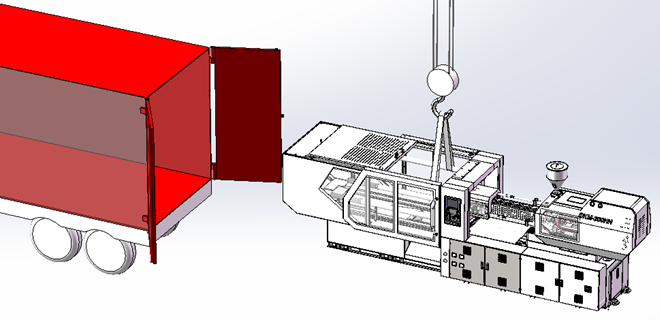

Sling the machine up to 100mm, and then pull it out of container, finally put it to the place where it shall be.

DKM-180SV Installation Process

Preparation before installation

1. Prepare a 5-10T sling, 5-10T Jack a, 1.5m and 0.5m level or a level of each one, the foundation bearing chart

The bearing requirements of the machine to the foundation are as follows

2. Customer needs to provide the factory floor plan and customer's water, electricity, gas preparation, in order to engineer installation and display

DKM-180SV Installation

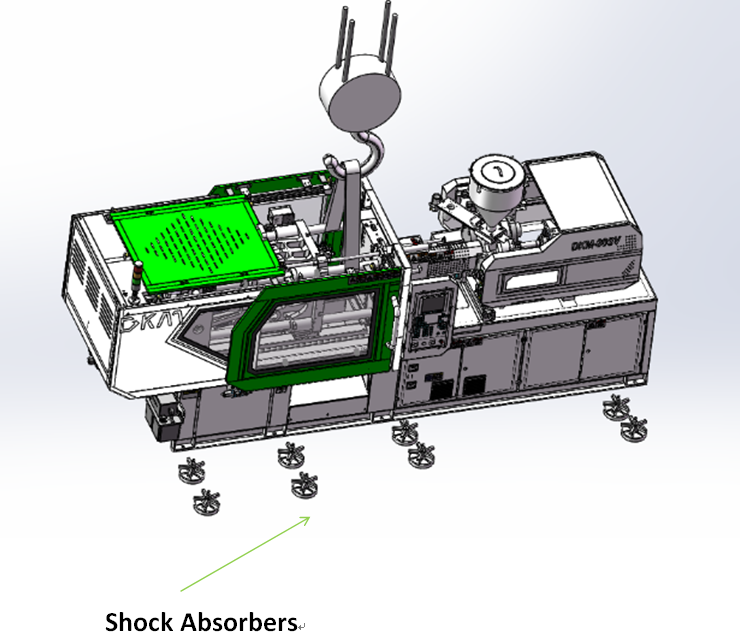

1. Determine the location of the installation of the machine, the machine into the installation location of the area, about 1m from the ground around the installation of shock absorbers.

Install the shock absorbers, put the machine into the designated position, and remove the sling.

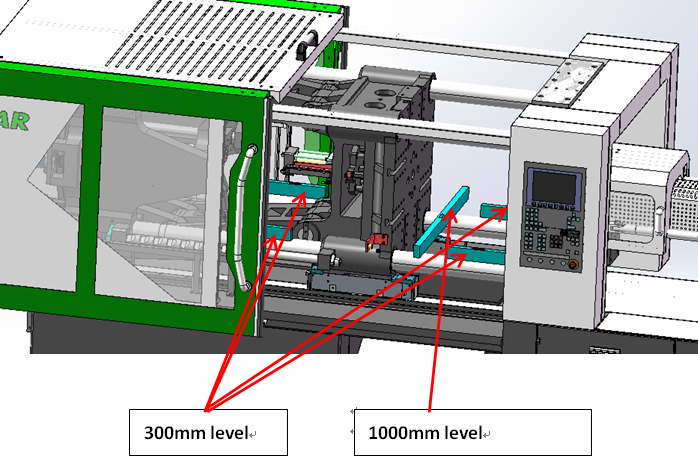

DKM-180SV Machine Level Alignment

1. Left and right

Put the level on the middle of tie bar, check that if bubbles is on middle. When the bubbles to left, it shows the left side is higher, need to adjust the right side to make it level. When it is right, adjust the left similarly.

2. Front and back

It is same as the left and right, just change the place for putting level: like the picture, it should be put on the middle between the tie bars.

Note: the difference shall not be greater than 0.05mm.

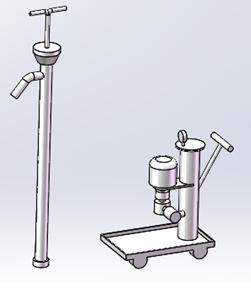

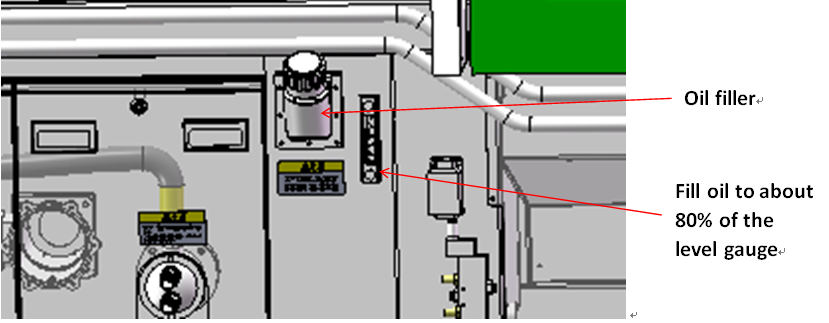

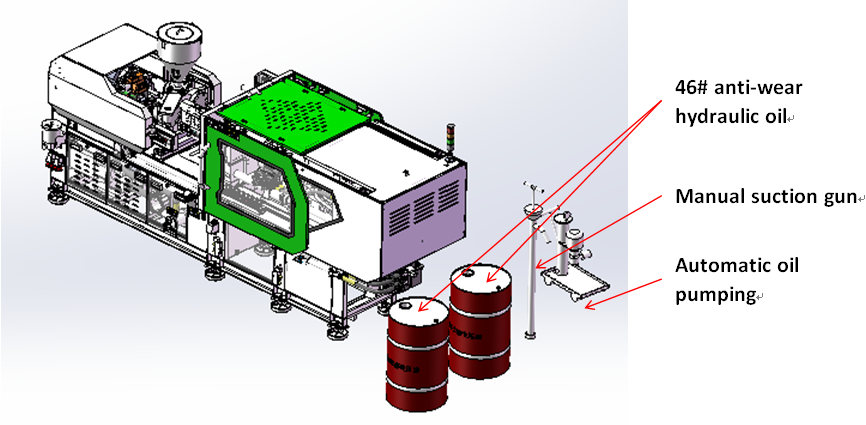

DKM-180SV Fill Hydraulic Oil & Connect Cooling Tubes for Machine

Fill hydraulic oil to the injection molding machine, 46# hydraulic oil for mean climatic temperature 0 ℃ to 40 ℃; 32# for about 0 ℃ to 10 ℃.

Auxiliary equipment needed for pumping unit (manual or semi-automatic)

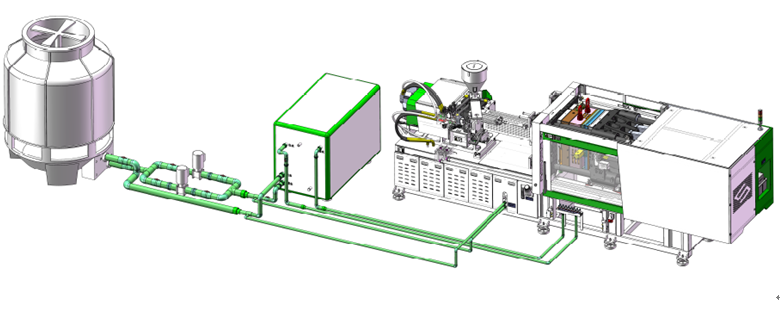

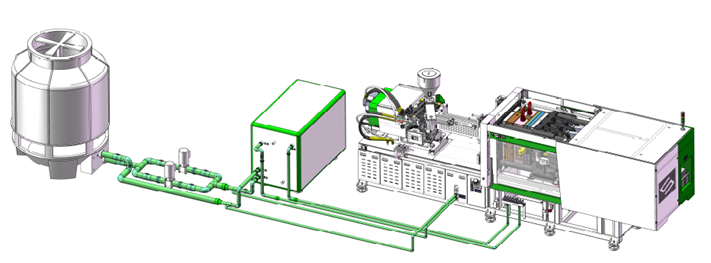

According to the water layout of workshop and local standard, connect the one inch of water pipe to machine cooling connector. Note, the principle for machine cooling connector is down in, up out or right in and left out.

DKM-180SV Electrical Connection Process and Notes

1. Inspection the voltage and frequency fit the machine specified. Check the nameplate, such as: 220V, 380V, 415V, 440V etc.

2. Select the corresponding cable to prevent the short circuit accident caused by over current.

3. heck the machine model、voltage、phase sequence, Prevent the wrong connection (cause equipment damage).

Machine power = voltage (V) * current (A), calculate the wire specifications, to match with the wire correctly.

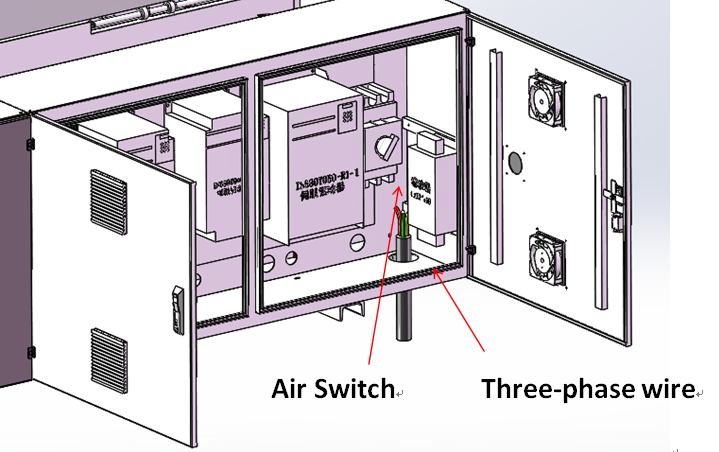

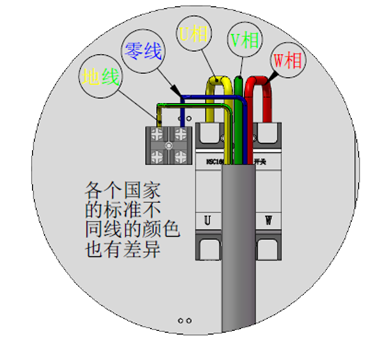

3.1. Connect the electricity according to the U/V/W. As the figure shows:

3.2. The zero line of distribution cabinet is connected to the N;

3.3. The ground wire of distribution cabinet is connected to the symbol of Ground Line.

4. Turn off electrical power and under the principle of up in down out, connect the power of the injection molding machine first, and then connect the distribution cabinet; to prevent the misoperation of others.

5. On equipment wiring,according to first connect the equipment on the line (switch off), then connect to the power distribution cabinet breaker (or air) principle; distribution cabinet wiring should first disconnect the circuit breaker, with a pencil or a multi-meter to test, to ensure that no voltage, lord it can be connected to power line equipment.

6. When supply the powers, turn on the distribution cabinet at first, and then turn on the equipment.

7. Turn off the power, turn off the equipment firstly, and then turn off the distribution cabinet.

8. When disconnecting wires, remove the power supply line of the distribution cabinet, and then remove the wires on the equipment.

9. During equipment repair, turn off the circuit breaker and sign the "do not turn on" on the main switch.

DKM-180SV Auxiliary Equipment Installation and Connect Power and Notes

Connect the auxiliary equipment to the injection molding machine or other machinery one by one.

1、 Dryer Installation (attached drawing)

2、 Auto Loader Installation (attached drawing)

3、 Chiller Installation (attached drawing)

1. All high-power auxiliary machines shall be connected on power distribution box.

2. For those auxiliary machineries, connected to plastic injection machine, check the power and the corresponding size of the aviation socket switch.

3. After testing, turn off all the machineries, avoid accident because of the dry running.

4. When connect the electricity, pay attention to the safety of electricity, only connect allowed when confirm no electricity.

5. When connecting powers, connect with the auxiliary equipment firstly, and then connect the distribution cabinet;

When disconnecting, remove the line of the power distribution cabinet at first, and then dismantle the power line on the equipment.